Battery Materials – Enabler Of Future Mobility

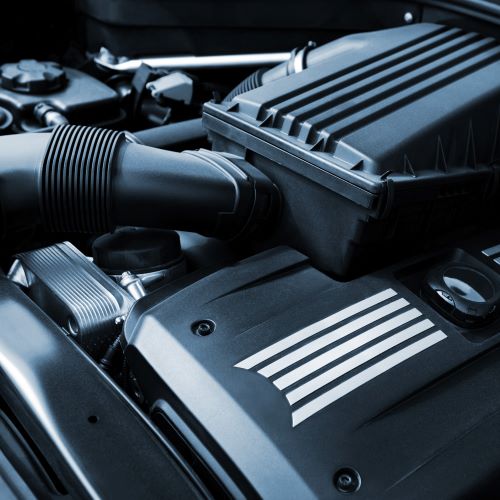

Asahi Kasei is a pioneer in the field of modern battery technology. Everything started when Asahi Kasei researcher Dr. Akira Yoshino developed the first working prototype of a lithium-ion battery in 1983. Today, the company is a market-leading supplier of lithium-ion battery separators, as well as for engineering plastics and foams. These materials significantly contribute to the safety, performance and size of batteries for electric vehicles.

Table Of Content

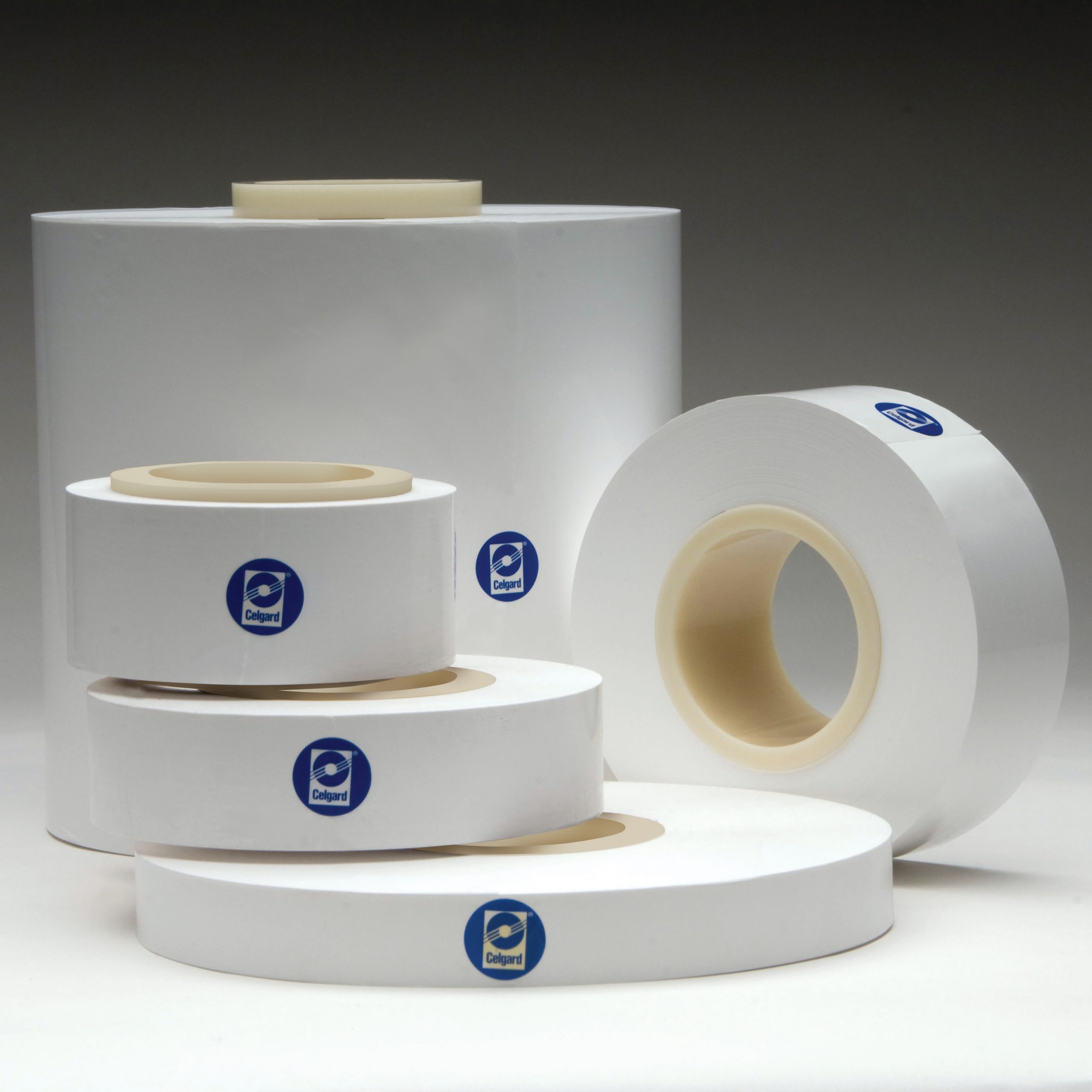

Celgard®

Dry-Process Lithium-Ion Battery Separators

Celgard, a subsidiary of Asahi Kasei since 2015, is a global leader in the development and production of high-performance membrane separator technology. The products are used in a broad range of energy storage applications. This includes rechargeable lithium-ion batteries, disposable lithium batteries and specialty energy storage.

As the world’s leader in battery separator technology, Celgard has both the expertise and the portfolio of product solutions required for next generation batteries.

Celgard offers products for a variety of battery separator applications that balance the competing demands of EDV performance criteria, including safety, chemical and dimensional stability, and cycle life.

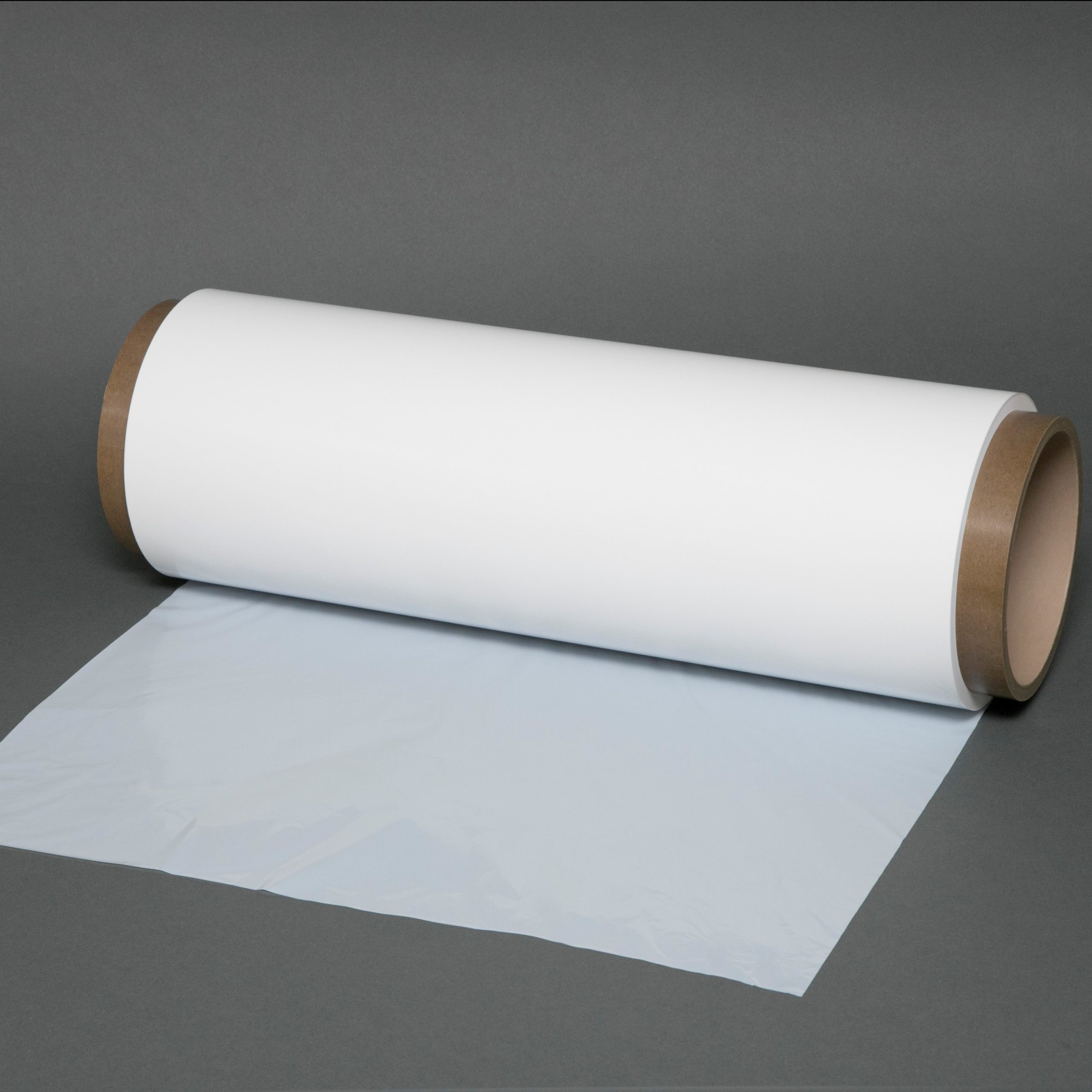

Hipore™

Wet-Process Lithium-Ion Battery Separator

Hipore™ is a high-performance microporous polyolefin flat membrane. With its broad thickness spectrum and very uniform and microscopically small pores, it is used as a separator in lithium-ion batteries. This wet-manufactured separator is used in lithium-ion batteries in automobiles as well as in consumer electronics such as smartphones and portable music players. Its high porosity provides an excellent liquid absorption capacity, while its high puncture resistance contributes to increased battery safety and reliability.

SunForce™ BE/BH

Increased Safety And Efficiency For The Automotive Battery

Optimizing weight, size, safety and efficiency of lithium-ion batteries is crucial to accelerate the electrification in the automotive industry. With the m-PPE particle foam SunForce™ BE/BH, Asahi Kasei developed a material addressing all these issues.

SunForce™ BE/BH is a particle foam based on the engineering plastic m-PPE (modified polyphenylene ether). Compared to standard foams made of polystyrene or polyolefin, the use of m-PPE equips this foamed material with unique properties, opening new doors for applications in thermal management and fire protection. The material is the first of its kind certified with UL 94 V-0 (Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances) fire protection class by the Underwriters Laboratories safety certification organization.

The material’s outstanding adhesive properties with other materials makes it suitable for sandwich composite core applications.

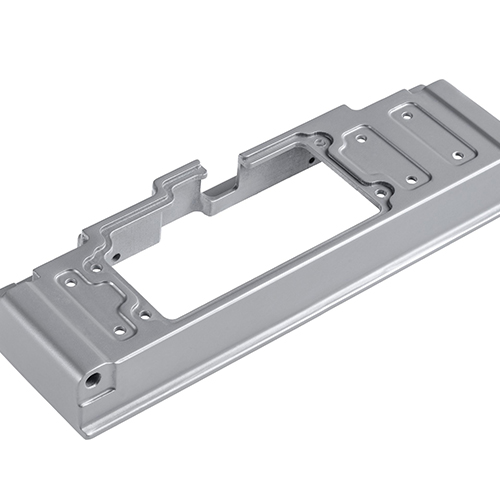

XYRON™

mPPE Lightweight Material

The modified polyphenylene ether (mPPE) XYRON™ is an engineering plastic with unique properties due to the possible combinations of polyphenylene ether (PPE) with polystyrene (PS), polyamide (PA), polypropylene (PP), polyphenylene sulphide (PPS) or other polymeric materials.

Applications for XYRON™ are to be found to a large extent in the automotive sector. Thanks to its low density – the lowest among engineering plastics – mPPE is suitable for a wide range of lightweight components, that are used, for example, for relay blocks, hood panels and brackets. However, concerning the current period of upheaval in the automotive sector, XYRON™ is especially used in the context of structural battery parts in the field of e-mobility. In this regard, the material contributes to a compact and weight saving battery design, at the same time leading to more efficiency as well as safety.