Automotive Solutions – Under the Hood

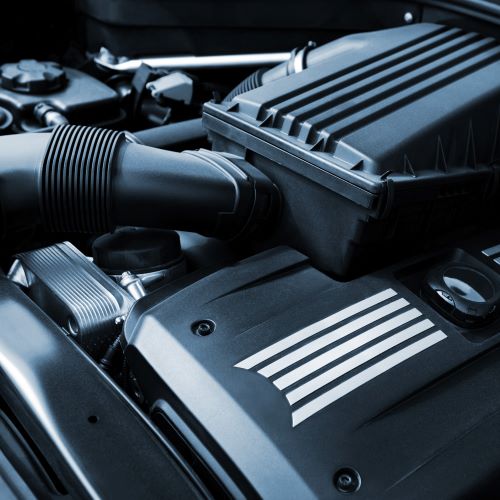

While the shift to battery electric vehicles is accelerating, internal combustion engines will continue to play a major role in the coming decades. In addition to downsizing and weight reduction, also the need for noise reduction is growing.

Regulations regarding the reduction of CO2 emissions and car noise levels have been significantly pushing the demand for new and innovative lightweight materials as a substitute for metal and aluminum parts. At the same time these materials have to live up to the high safety standards in the automotive industry, and to provide solutions to the changing and tightening regulations worldwide. Plastics, foams and performance fibers with their broad range of properties will become a key in this field, contributing to a reduction of CO2 emissions of conventional passenger cars with an internal combustion engine.

LEONA™ Polyamide 66

The Allrounder For Advanced Metal Replacement

Today’s push for engine downsizing and lightweight, using turbochargers, high pressure injection and other combustion engine designs, lead to higher heat, pressure, thermal and mechanical stresses. Integrating plastics into these parts help OEMs achieve their goals for durability, NVH and customer satisfaction.

Asahi Kasei’s LEONA™ polyamide-based compounds convince with their high heat resistance, their mechanical properties, as well as with their resistance against oils and chemicals – therewith fully matching the ICE related applications requirements.

Do you have more questions?

Our team of experts welcomes you

Use our contact form to reach out to us.