A Class-A Surface Material With Low Emissions And Excellent Scratch Resistance

Düsseldorf, July 15, 2020 – Asahi Kasei Plastics North America (APNA) introduces SoForm™, a new engineered resin series as part of their diverse Thermylene® family – Asahi Kasei’s portfolio of specialty chemically coupled glass fiber reinforced polypropylenes. SoForm™ is a cost- and process-optimized material for automotive interior surfaces and industrial durable goods.

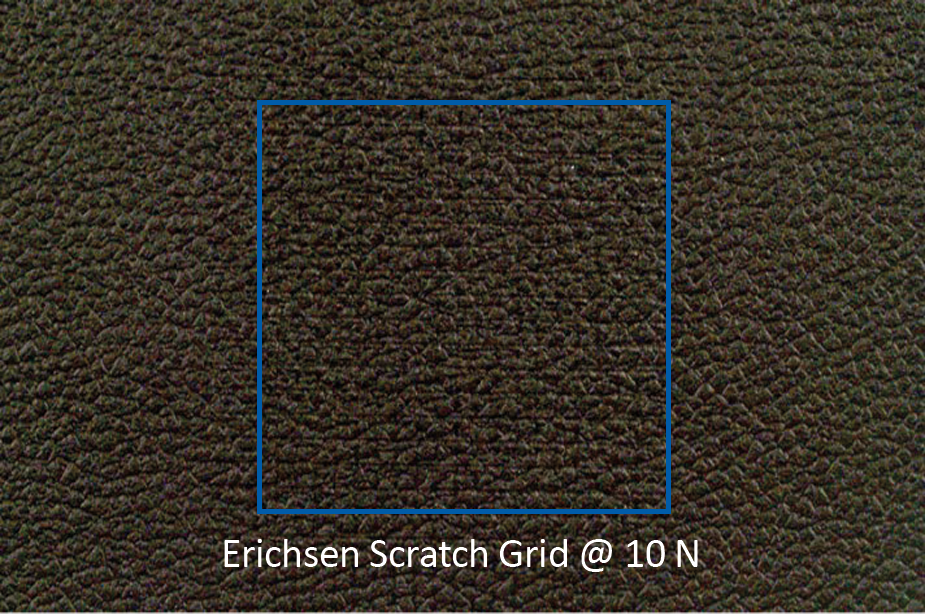

SoForm™ features excellent scratch resistance with haptic surface feel and improved durability compared to competitors. It also offers key benefits such as low gloss, low emissions, chemical resistance, and structural performance.

“Durability coupled with low gloss and improved haptic surface feel are key to interior performance and customer end use criteria now more than ever; SoForm™ provides an attractive solution to meet these demanding requirements” states Jane Horal, Marketing and Business Development Manager at APNA.

The material is available in 10%, 15%, 20% and 25% glass fiber filled grades. All are commercialized and available in either natural or pre-colored for injection molding.

A cost-saving and eco-friendly alternative

Automotive application areas for these novel grades include, but are not limited to, instrument panels, door panels and associated touch points (map pockets, console sides, mirror surrounds and seat trim).

SoForm™ also excels in the industrial segment with applications such as furniture armrests and durable wear surfaces. The durability and haptic surface finish enable both automotive and industrial segments to provide customers with improved longevity and luxury.

“SoForm™ has unique performance compared to traditional talc reinforced thermoplastic elastomers due to the increased scratch and mar properties” says Todd Glogovsky, VP of Sales and Technology at APNA. “For applications that have higher durability requirements, SoForm™ will be a key product”

Currently, soft touch paint, over-molding or a foam in place with skin has been required to meet these customer demands. SoForm™ is an alternative to improve the design, manufacture, logistics and value chain of the production process. As the material eliminates the needs to paint, over-mold or foam in place, it can provide additional cost-savings and eco-friendly options for the manufacturer.

You can find more information on the new material on its dedicated landing page:

About the Asahi Kasei Corporation

Asahi Kasei Corporation is a globally active diversified technology company with operations in the Material, Homes, and Health Care business. The Material division encompasses fibers & textiles, petrochemicals, performance polymers, performance materials, consumables, battery separators, and electronic devices. The Homes division provides housing and construction materials to the Japanese market. The Health Care division includes pharmaceuticals, medical devices, and acute critical care devices and systems.

With more than 40,000 employees around the world, the Asahi Kasei Group serves customers in more than 100 countries and achieved sales of 17.6 billion euros (2,151.6 billion yen) in the fiscal year 2019 (April 1, 2019 – March 31, 2020). Asahi Kasei is Japan’s largest polyamide supplier and is one of only four fully integrated polyamide manufacturers worldwide – able to produce PA 6.6 completely from monomer to compound.

Asahi Kasei is “Creating for Tomorrow” with all operations sharing a common mission of contributing to life and living for people around the world. For more information, visit www.asahi-kasei.eu and www.automotive.asahi-kasei.eu

Company Contact Europe:

Asahi Kasei Europe GmbH

Sebastian Schmidt

Fringsstrasse 17, 40221 Düsseldorf

Tel: +49 (0) 211-3399-2058

Mail: sebastian.schmidt@asahi-kasei.eu